Kladana lets you create a professional schedule of the cost of goods manufactured without the hassle of manual data entry. All your production cost details are compiled into clear, structured reports. We’ve already explored the formula and critical components of COGM, but let’s consider the practical example as well. We’ll also review its formula, understand its components, and outline the key differences between COGM and the Cost of Goods Sold (COGS) for better clarity.

- Our rigorous editorial process includes editing for accuracy, recency, and clarity.

- Strengthening infrastructure and public-private partnerships will further support this growth and benefit related sectors like logistics and IT.

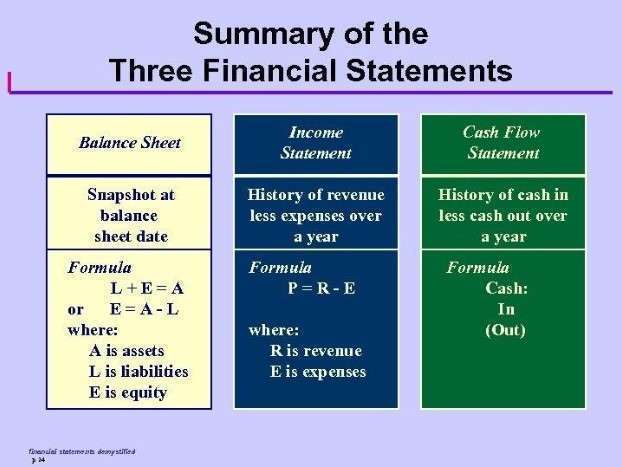

- Under the matching principle of accrual accounting, each cost must be recognized in the same period as when the revenue was earned.

- Remember that this is merely an illustration and that the precise COGM costs may change based on the business and the product being produced.

- The origin of this term dates back to management accounting practices in 1920s America, when businesses began tracking costs related to production more closely than ever before.

- Let’s dive into practical tips and solutions to make COGM calculations smoother and more accurate.

- You add the value of raw materials and work-in-progress inventory at the start of the period to all the costs of making products during the period and subtract the value of inventory at the end of the period.

Calculate COGM Using Cloud ERP Software: Kladana

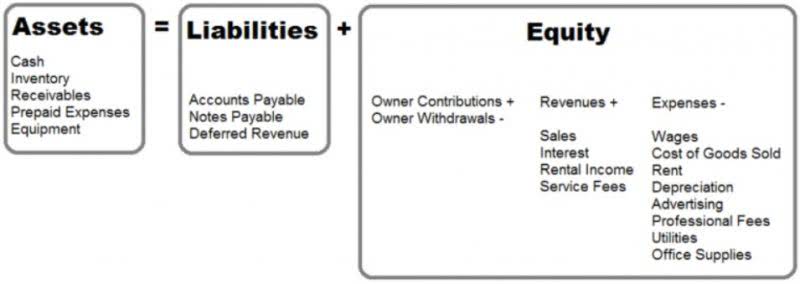

WIP is a current asset in the company’s balance sheet and represents the total value of all materials, labor, and overhead of unfinished products. In order to determine the actual direct materials used by the company for production, we must consider the Raw Materials Inventory T-account. Raw materials inventory refers to the inventory of materials that are waiting to be used in production. For example, if a company were to make a raw material purchase for use, these would be recorded in the debit side of the raw materials inventory T-Account. The Cost CARES Act of Goods Manufactured (COGM) is a critical metric for companies seeking accurate insights into their production costs and profit margins. Implementing software solutions for COGM can greatly enhance accuracy and efficiency, allowing businesses to focus more on growth and less on complex manual calculations.

Role in Financial Statements

That can be a cost-effective option for many companies, especially the ones in the eCommerce industry. Outsourcing management of finished goods inventory means you can focus on other aspects of the business such as marketing or sales. In addition, reputable 3PL providers give their customers the same benefits as an ERP solution – traceability, automation, demand forecasting, and many more. Finished goods inventory has a big effect on the cost of goods sold (COGS). That’s because a manufacturer creates revenue when finished goods inventory is sold.

Forecast Cost of Goods Sold (COGS)

These three primary components make up any business’s total manufacturing cost. In summary, COGM reflects the total cost of manufacturing goods – whether they were sold or not – while COGS represents the cost of only those goods that were sold to customers during a specific period. To determine COGS, start with the beginning finished goods inventory, add the cost of the products produced throughout the period, and then deduct the ending finished goods inventory. COGS is a financial accounting measure representing the direct costs of producing and selling goods. Cloud manufacturing software such as Katana allows businesses to use data from their operations to calculate COGM and other vital figures like inventory value and sales revenue.

Create a free account to unlock this Template

Learn financial statement modeling, DCF, M&A, LBO, Comps and Excel shortcuts. If we enter those inputs into our WIP formula, we arrive at $44 million as the cost of to calculate cost of goods manufactured add goods manufactured (COGM). Suppose a manufacturer is attempting to calculate its cost of goods manufactured (COGM) for 2021, its most recent fiscal year. In spite of the similarities in the names, the cost of goods manufactured (COGM) is not interchangeable with the cost of goods sold (COGS).

- It’s a good idea to calculate COGM at the end of each accounting period, such as monthly or quarterly.

- Then, add it to the purchases of raw materials made during the period and subtract it from the ending raw materials inventory, which is the number of raw materials on hand at the end of the period.

- They’ll be able to adapt quickly to changes in the market and stay ahead of the competition.

- But not all labor costs are recognized as COGS, which is why each company’s breakdown of their expenses and the process of revenue creation must be assessed.

- It encompasses material costs, labor costs, and manufacturing overhead, adjusted for the change in work-in-progress inventory.

- Kladana doesn’t stop at calculating your COGM — it provides actionable insights from the data it gathers.

Cost of Direct Labor

Whether you’re a small manufacturer or a large-scale operation, this software Car Dealership Accounting can help you stay on top of your COGM calculations and make better financial decisions. COGM is also closely tied to the Cost of Goods Sold (COGS), which represents the cost of finished goods that have been sold to customers. Both metrics are essential for understanding your business’s financial health. Direct materials, direct labor, manufacturing overhead, and adjustments for work-in-process (WIP) inventory.

- The Cost of Goods Manufactured (COGM) is all about figuring out what it costs to make stuff.

- Labor costs involve salaries, commissions, and benefits tied to production hours, including any overtime.

- It provides a comprehensive view of production costs, crucial for pricing, budgeting, and financial analysis.

- To use the periodic inventory system, purchases related to manufactured goods must be accumulated in a “purchases” account.

- The main components of COGM are direct materials, direct labor, and manufacturing overhead.

- While the gross margin is the standard metric used to analyze the direct costs of a company, the COGS margin is the inverse (i.e., one subtracted by gross margin).

How do I calculate cost of goods sold (COGS)?

At the end of the quarter, $8,500 worth of furniture is still unfinished as calculated by the MRP system. Let us look at an example of the COGM calculation for a furniture manufacturer. The company has $5,000 worth of furniture in the making at the start of the fiscal quarter. The following equation is used to calculate the COGM, or cost of goods manufactured. Get instant access to video lessons taught by experienced investment bankers.